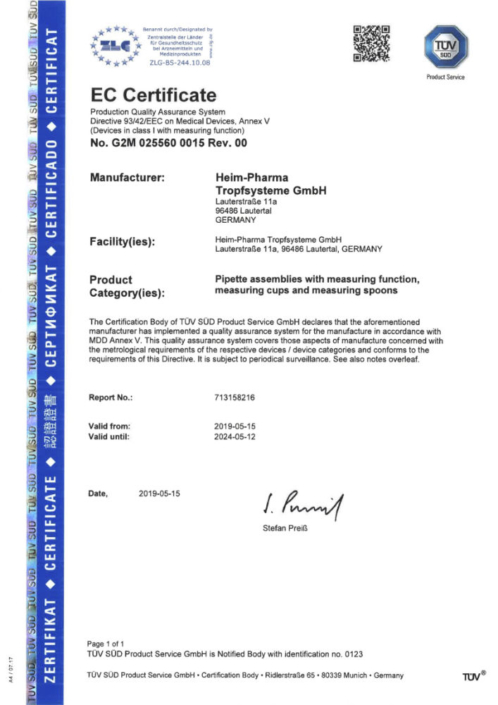

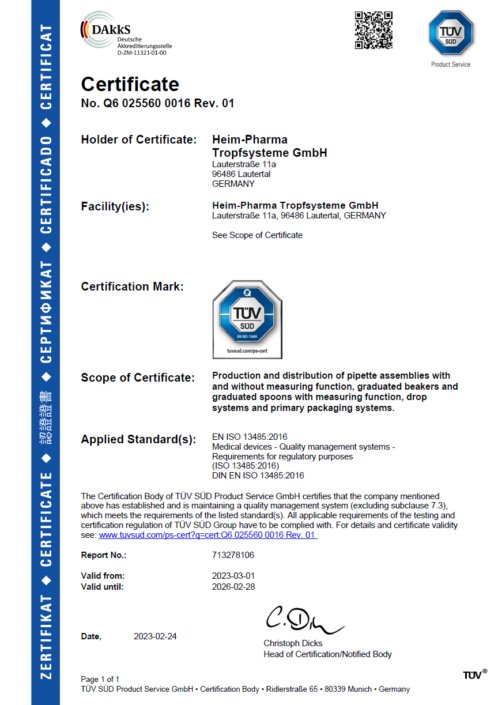

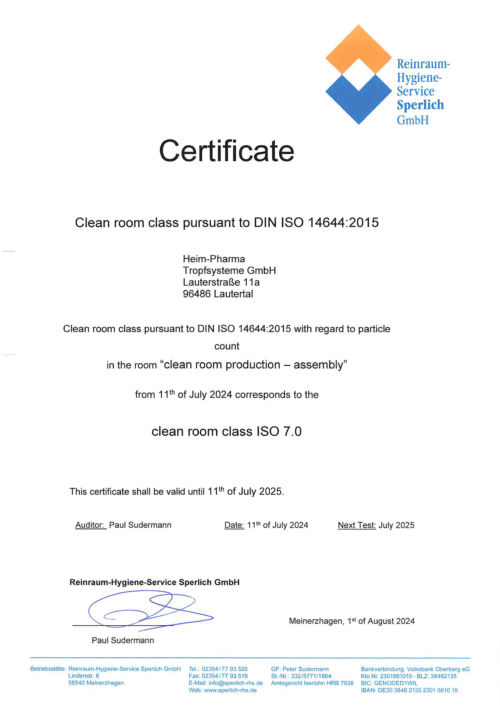

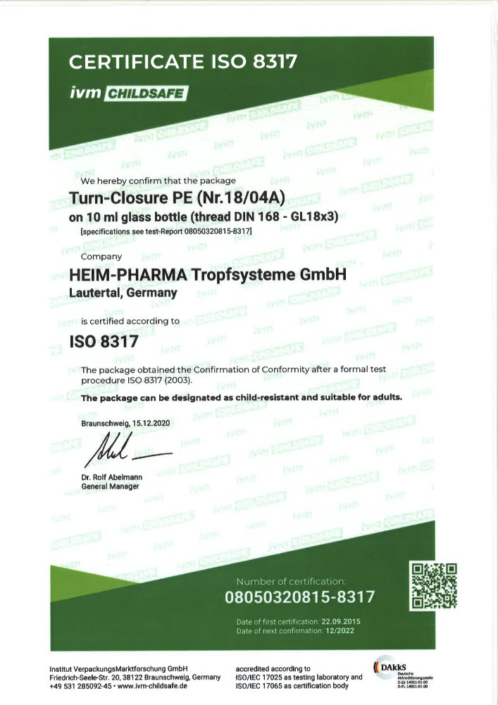

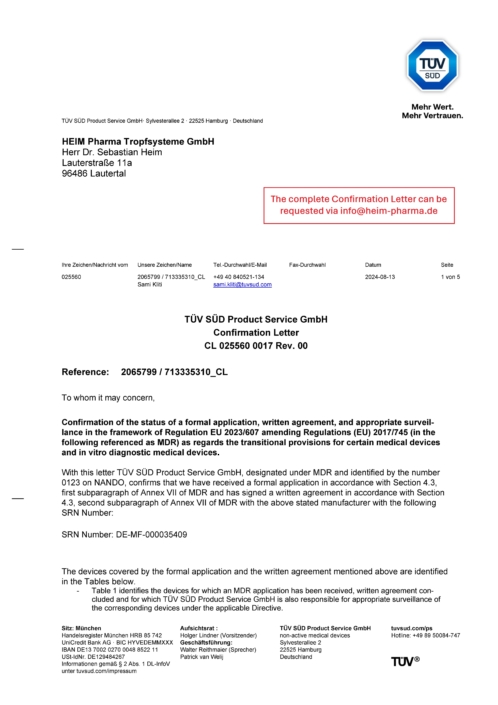

Quality: five different certifications

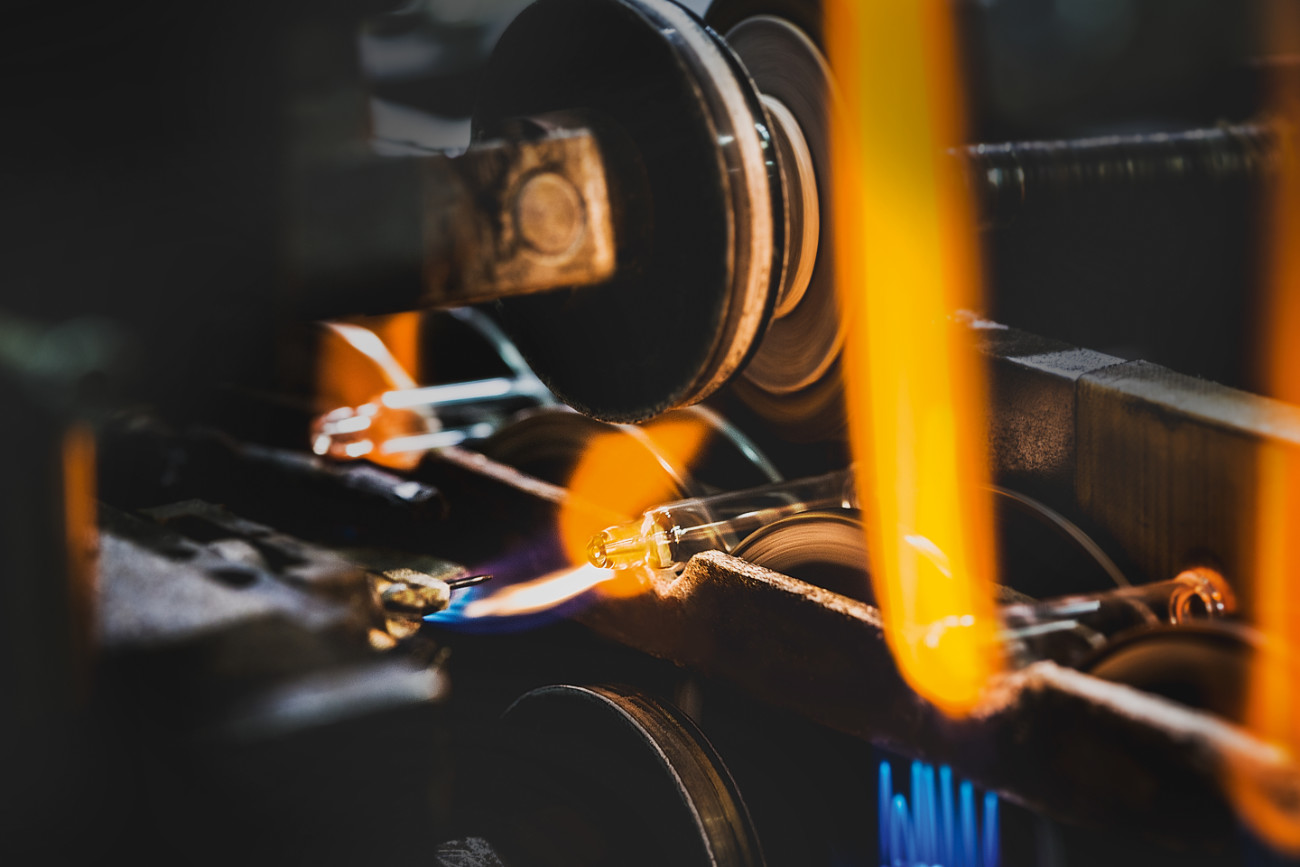

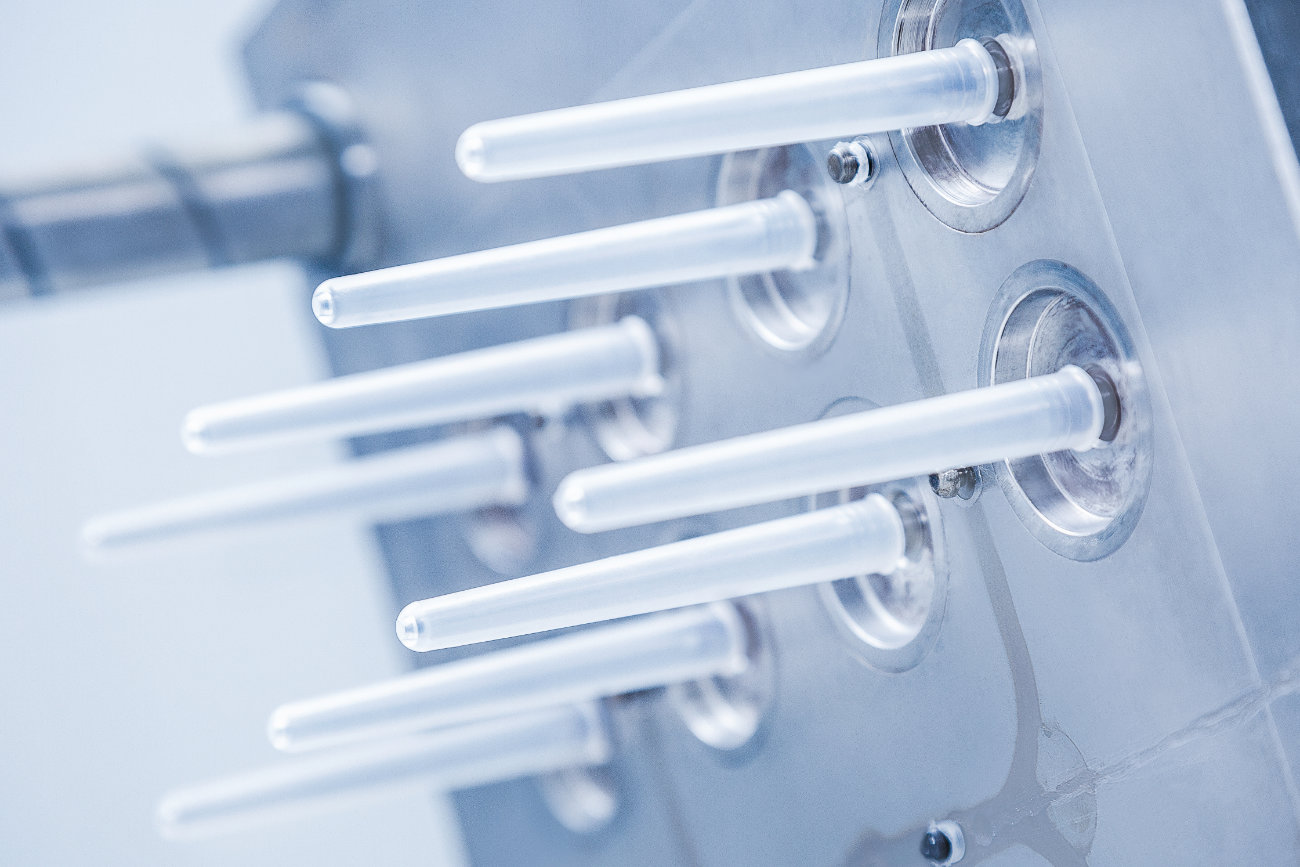

Our many different certificates show our partners and customers that they can rely on us completely when it comes to the quality and purity of their metering and dropper systems. As a leader in innovation, we are constantly working on solutions that go beyond even our own standards.